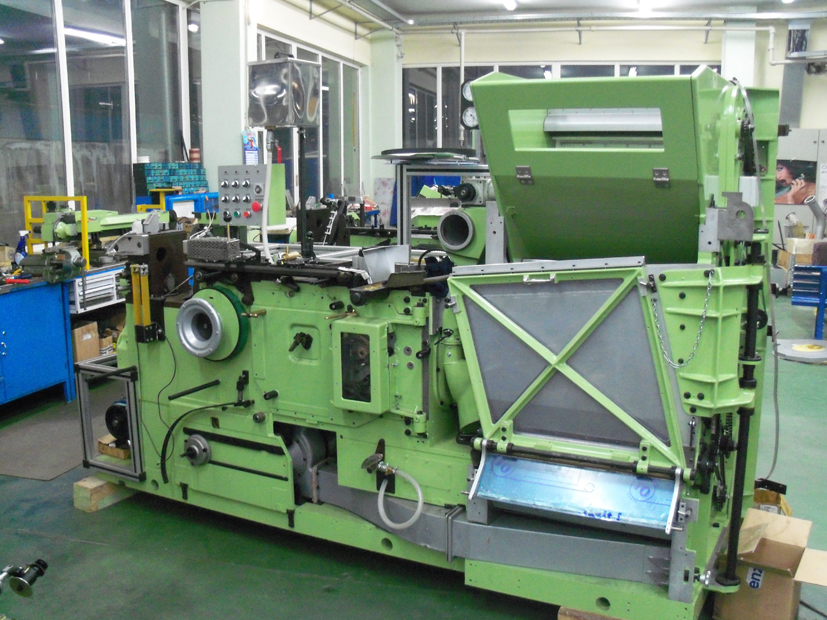

MK9 Cigarette Making Machine

MK9 Cigarette Making Machine

Product Overview

The MK9 Cigarette Making Machine is a robust, high-capacity solution designed for large-scale cigarette manufacturing. Renowned for its precision and reliability, the MK9 can produce up to 5,000 cigarettes per minute, making it a preferred choice for high-volume production facilities. Its advanced technology ensures consistent quality while minimizing waste and downtime.

Benefits

Maximized Output

- Industry-leading production speed

- Continuous operation capability

- Minimal downtime

- Optimized efficiency

Superior Quality

- Precise tobacco control

- Consistent cigarette formation

- Uniform filter attachment

- Quality monitoring systems

Operational Efficiency

- Reduced material waste

- Automated quality control

- Energy-efficient operation

- Streamlined production flow

Versatility

- Multiple cigarette sizes

- Various filter options

- Different tobacco blends

- Customizable parameters

Use Cases

High-Volume Production Facilities

- Perfect for large-scale manufacturing

- Continuous production capabilities

- Maximum output efficiency

- Quality-focused operations

Custom Cigarette Manufacturing

- Multiple size configurations

- Blend variety handling

- Special filter integration

- Market-specific production

Export-Oriented Production

- International quality standards

- High-volume capability

- Consistent product quality

- Reliable performance

Technical Features

Control System

- Advanced PLC controller

- Touch screen interface

- Real-time monitoring

- Production data logging

Tobacco Handling

- Precise cutting mechanism

- Density control

- Even distribution

- Minimal waste

Filter Integration

- Multiple filter compatibility

- Precise alignment

- Secure attachment

- Quality verification

Safety Systems

- Emergency stops

- Safety interlocks

- Guard monitoring

- Operator protection

Maintenance and Support

Regular Maintenance

- 1,000-hour service intervals

- Preventive maintenance programs

- Performance optimization

- Component inspection

Technical Support

- 24/7 global assistance

- Remote diagnostics

- Emergency response

- Expert consultation

Training Programs

- Comprehensive operator training

- Maintenance staff education

- Advanced troubleshooting

- Best practices instruction

Integration Capabilities

Production Line

- Seamless line integration

- High-speed synchronization

- Quality control systems

- Material handling coordination

Data Systems

- Production monitoring

- Quality data tracking

- Performance analytics

- Industry 4.0 ready

Customization Options

- Special size requirements

- Custom filter integration

- Specific blend handling

- Market-specific features

Customer Success Story

“The MK9 has revolutionized our production line. Its speed and reliability have helped us meet growing demand without compromising on quality. Since implementation, we’ve seen a 40% increase in output while maintaining our high quality standards.” – Sarah Lee, Operations Director at Global Tobacco Co.

Next Steps

Request a Quote

Speak with our experts to learn how the MK9 can enhance your operations.

Download Resources

- Detailed specifications

- Technical documentation

- Maintenance guidelines

- Integration requirements

Get Support

Our technical team is ready to assist with:

- Production planning

- Integration strategy

- Training requirements

- Maintenance programs

Technical Specifications

| Production Capacity | Up to 5,000 cigarettes per minute |

|---|---|

| Cigarette Length | 70 mm to 120 mm |

| Cigarette Diameter | 5.4 mm to 8 mm |

| Filter Length | 15 mm to 30 mm |

| Power Supply | 440V (3-phase), 50Hz ±1Hz |

| Machine Dimensions | 4500 mm (L) x 1600 mm (W) x 2200 mm (H) |

| Weight | Approximately 7,500 kg |

Key Features

map[description:Produces up to 5,000 cigarettes per minute for high-volume operations title:Exceptional Speed]

map[description:Integrated cutting-edge systems for precise tobacco cutting, wrapping, and assembly title:Advanced Technology]

map[description:Engineered for long-term performance in demanding environments title:Durable and Reliable]

map[description:Supports various cigarette sizes, diameters, and filter types title:Flexible Configurations]

map[description:Intuitive controls for seamless operation and monitoring title:User-Friendly Interface]

Applications

Large-scale cigarette production

Export-oriented manufacturing

Custom cigarette production

High-volume facilities

International market supply

Optional Add-ons

- Advanced Filter Attachment

- Automatic Tray Collector

- High-Precision Spare Parts Kit

- Production Monitoring System

- Extended Warranty Package

Support & Maintenance

- 1-year comprehensive warranty

- 24/7 technical support

- Regular maintenance every 1,000 hours

- Global on-site service

- Operator training programs